FILLING AND CAPPING MONOBLOCK

Model Number: FCM

Acquirable in Upcoming Events:

Acquirable in Upcoming Events:

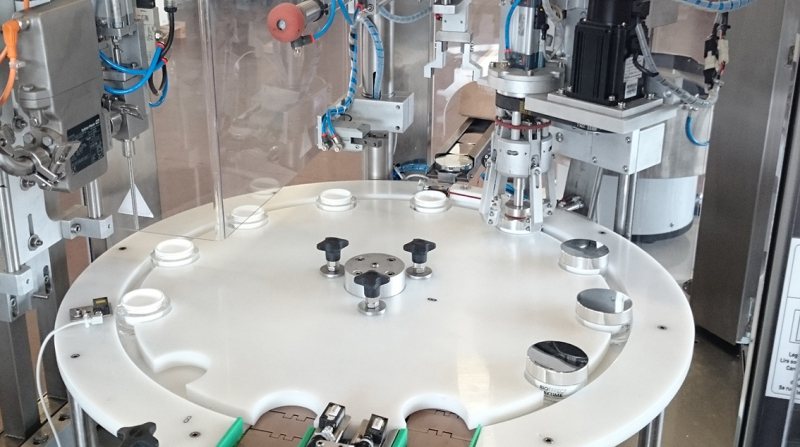

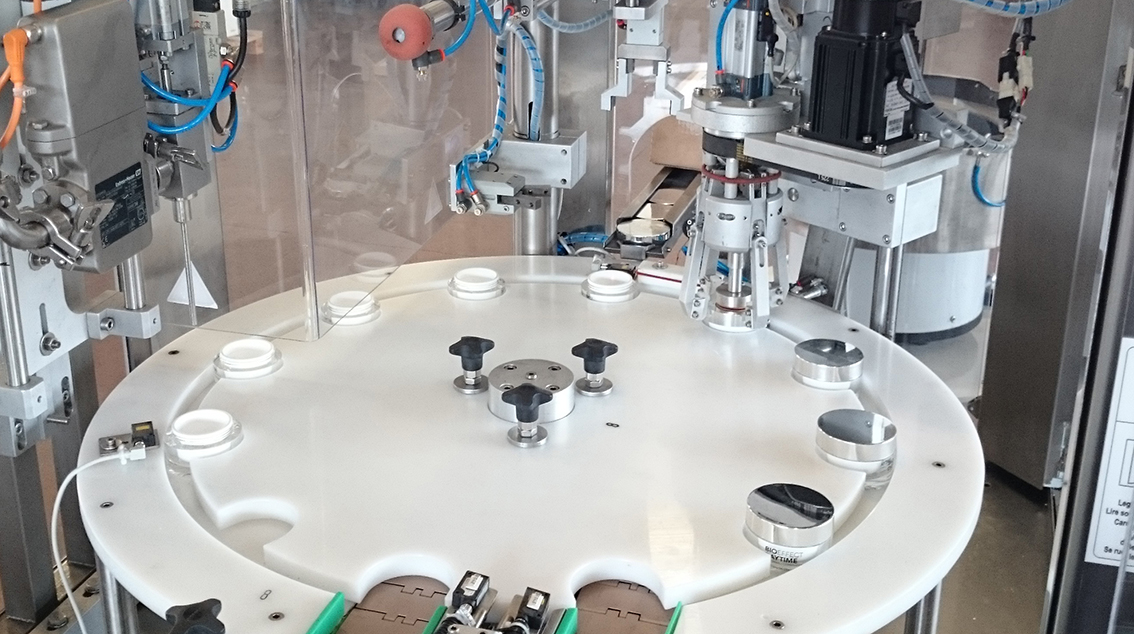

Packaging solution for creams an serums designed to handle 3 different containers, screw caps and dropper caps. The plant is equipped with a 16-positions transport star, with interchangeable product shapes, in plastic material and operated by an intermittent mechanical group with adjustable working speed. Dosing station with flowmeters suitable for creamy products driven by a brushless motor, adjustable for ranges from 1 to 75 cc. Immersion dosing nozzle complete with thread cutting system. Loading hopper with 20 l capacity, with level sensor.

Undercover station composed of vibrating selector, conveyor belt, Pick & Place system to take undercaps and position them on containers.

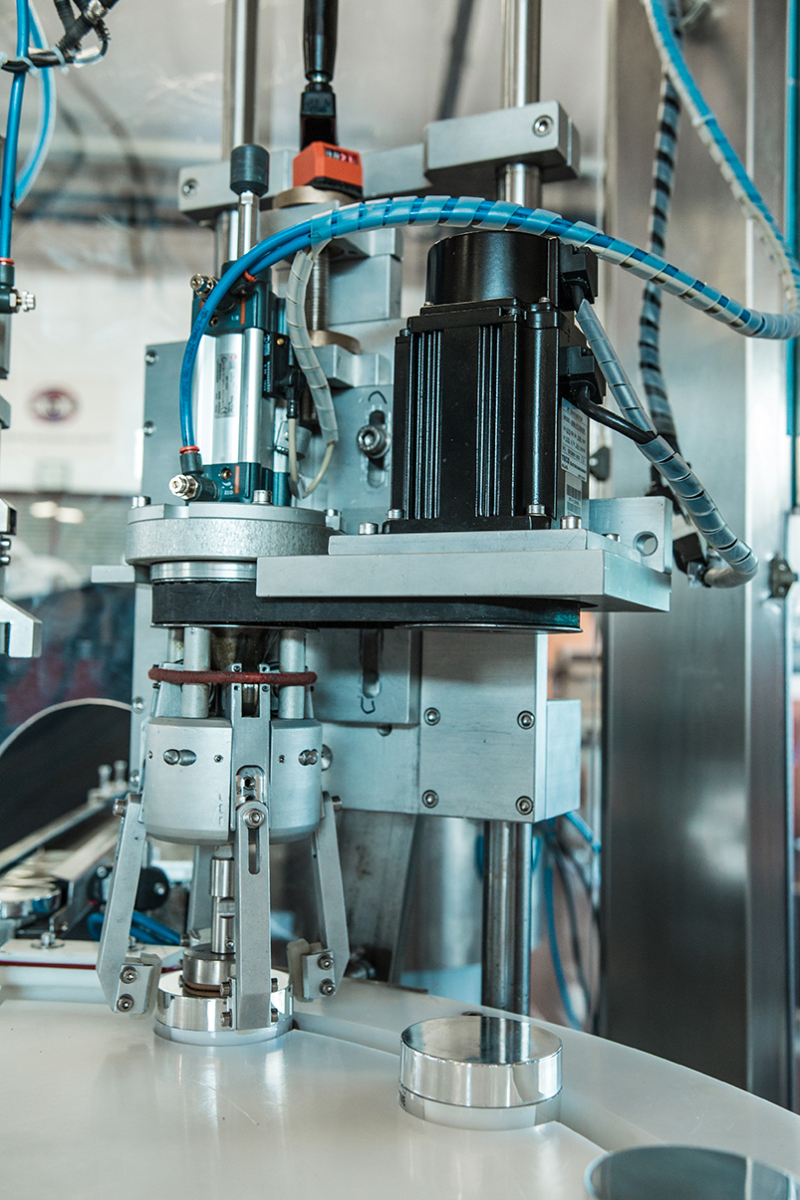

Caps feeding station, composed of vibrating selector, conveyor belt, Pick & Palce system to take caps and place them on containers. The screwing unit has a closing head for screw caps, operated by a pneumatic motor with tightening torque adjustment. The unit is installed on a vertical guide adjustable in height to facilitate format change. Production: about 800 pcs/h, depending on the size of the container.

Undercover station composed of vibrating selector, conveyor belt, Pick & Place system to take undercaps and position them on containers.

Caps feeding station, composed of vibrating selector, conveyor belt, Pick & Palce system to take caps and place them on containers. The screwing unit has a closing head for screw caps, operated by a pneumatic motor with tightening torque adjustment. The unit is installed on a vertical guide adjustable in height to facilitate format change. Production: about 800 pcs/h, depending on the size of the container.

Lead Time

1 months

Payment Types

![]()

Port

Main Export Markets

Africa, Asia, Australia, Europe, Latin America, Middle East, North America